IntelliSuite software solves the difficulty of etching process in MEMS design!

- Categories:Software case

- Author:

- Origin:

- Time of issue:2022-07-03

- Views:996

IntelliSuite software solves the difficulty of etching process in MEMS design!

(Summary description)

- Categories:Software case

- Author:

- Origin:

- Time of issue:2022-07-03

- Views:996

The lntelliSuite software can analyze the impact of key etching processes on the device structure. The etching process includes wet etching and dry etching.

Wet etching of silicon

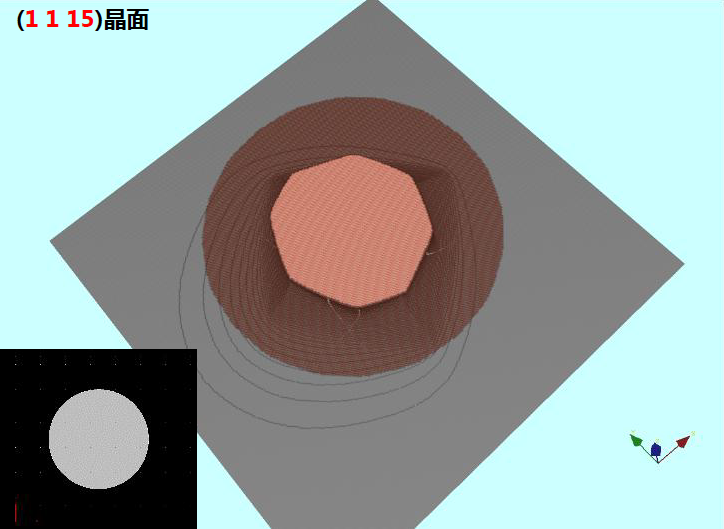

1. High-order crystallographic etching

The wet etching engine of the physical-level process simulation module Fabsim can perform high-order crystal orientation etching. Users can set the required crystal orientation index in the defined substrate parameters in the process editor IntelliFab. It can be seen from the figure below that different crystal orientations have different morphologies after etching under the same etching conditions.

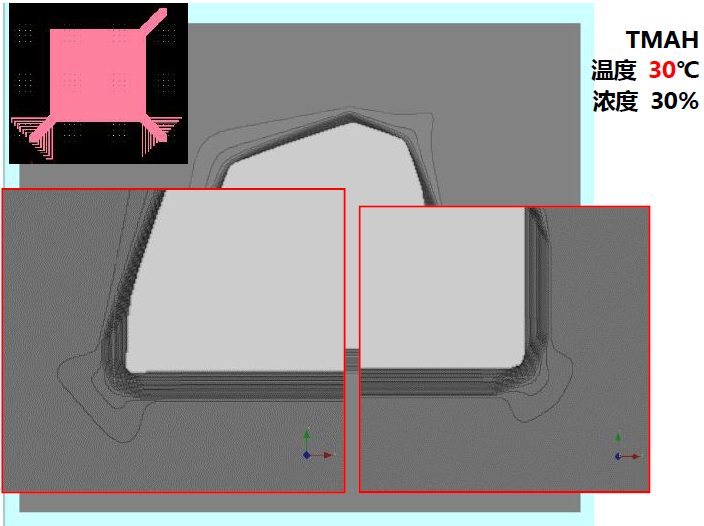

2. Influence of etching parameters

Fabsim wet etching presets the influence of parameters such as temperature and etching solution concentration on the etching rate. Users can modify the corresponding parameters in IntelliFab. The figure below shows the difference in corrosion morphology at different temperatures under the same other conditions.

3. Effect of etchant

Fabsim wet etching allows users to perform etching simulations of various etching solutions, and users can add etching steps of different etching solutions in IntelliFab.

dry etching

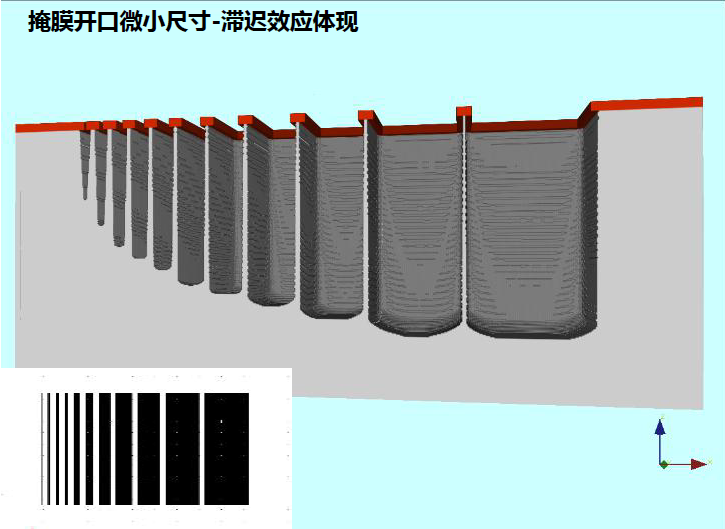

1. Hysteresis effect

The dry etch engine in Fabsim has the ability to simulate the hysteresis effect (ARDE effect) at very small size openings.

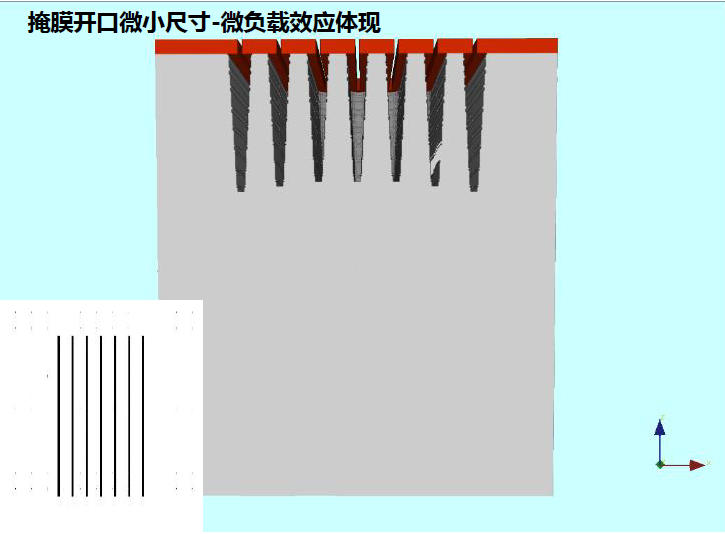

2. Micro-load effect

The dry etch engine in Fabsim is capable of simulating micro-loading effects under tiny size openings.

3. Preset parameters

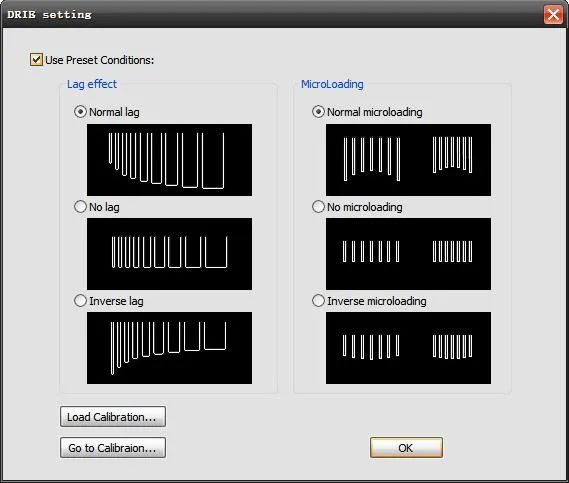

IntelliSuite provides preset parameters to achieve various combinations of hysteresis effects and microloading effects in dry etching, which users can set in IntelliFab's DRIE etching parameters.

DRIE Etch Parameters for IntelliFab

Various combinations of hysteresis and microload effects

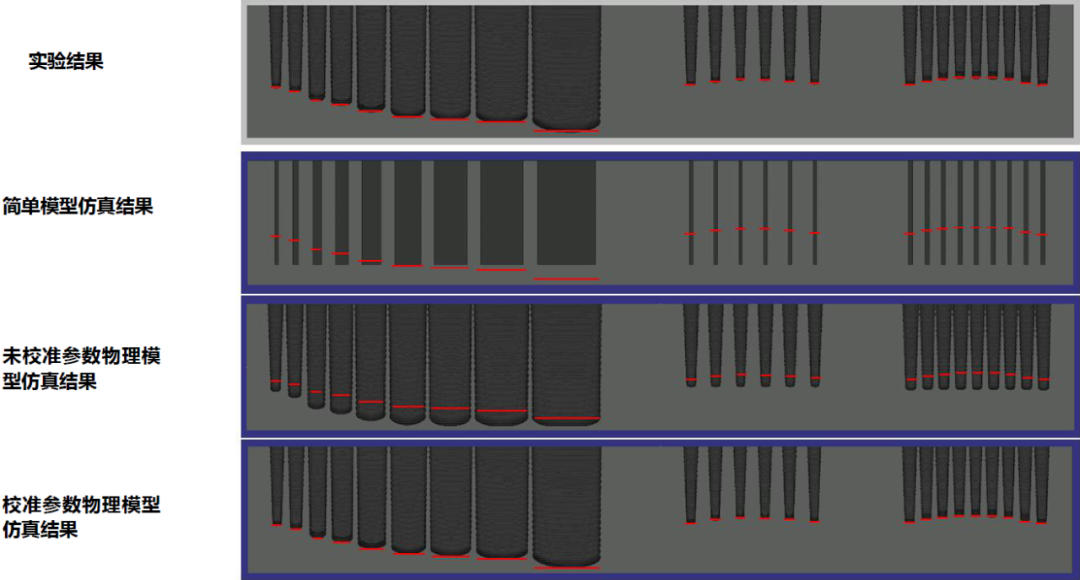

4. Calibration tool

IntelliSuite provides a calibration tool for the preset parameters of the Fabsim dry etching engine. This tool can extract the etching depth data to calibrate the parameters of the etching engine according to the specific experimental results, so as to achieve etching simulation results consistent with the real etching results.

Scan the QR code to read on your phone

Applications

Learn how Intellisense can help you?

E-mail:china@intellisense.com

Add:No. 19, Lixin Road, Nanjing Jiangbei New Area, Nanjing City, Jiangsu Province

Copyright © 2022 Jiangsu Intellisense Technology Co.,Ltd. 苏ICP备08107867号 Powed by:300.cn SEO

Tel

Tel Messages

Messages Top

Top