CATEGROIES

AnisE

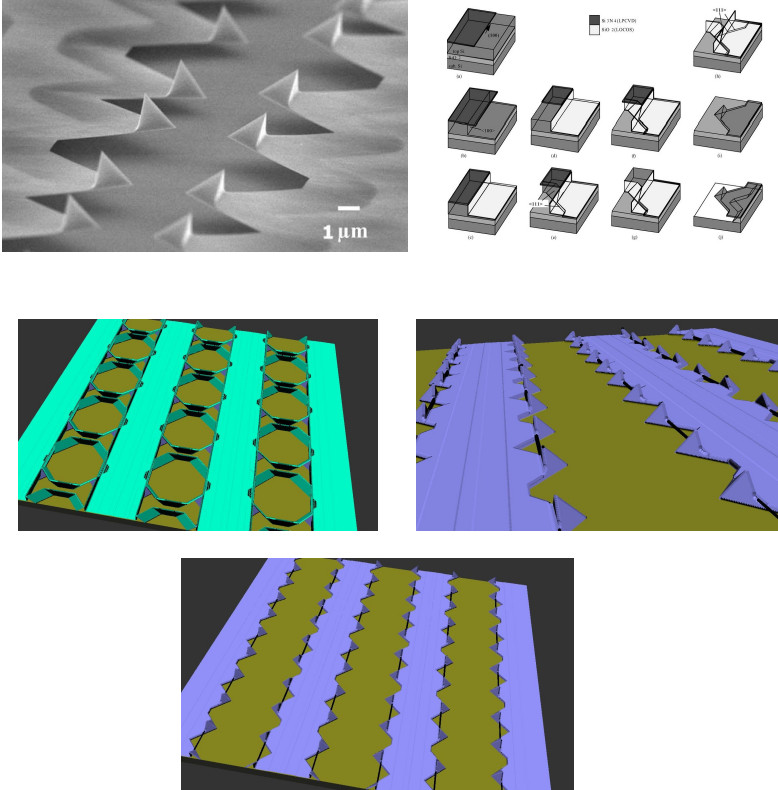

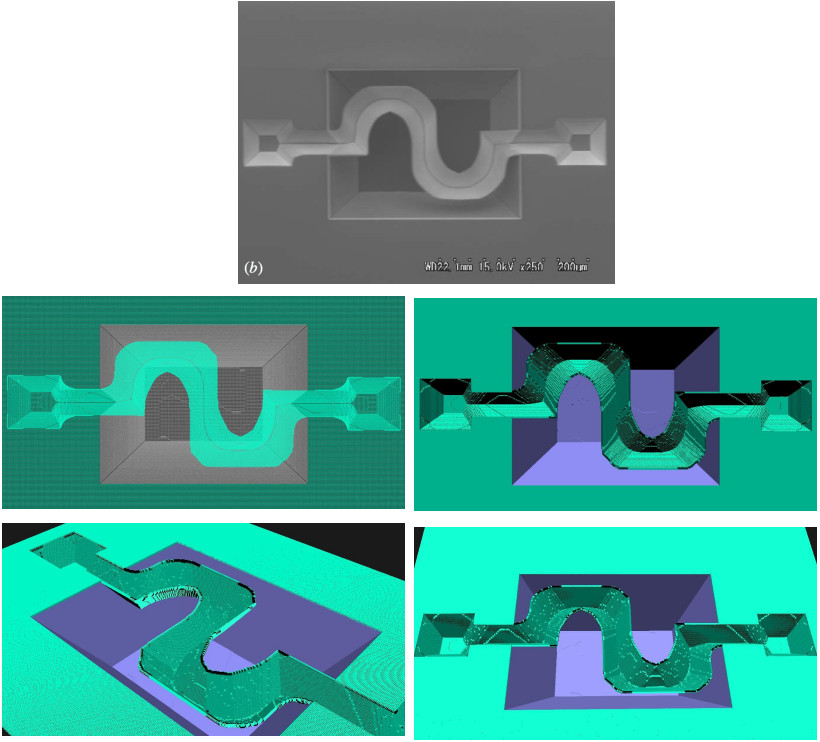

The advanced, automatic control-based unit etching simulation technology can obtain accurate <100>, <110> single crystal silicon wafer KOH and TMAH anisotropic etching simulation results, and can also be used for complex layout and long-term etching.

◆ Top, bottom and double-sided etching of wafers;

◆ Multiple cut-off layers and multiple etchings of different masks on a single wafer;

◆ Reflect the impact of misaligned masks, and compensation techniques;

◆ Predict the influence of etchant temperature, concentration and etching time on device shape;

◆ TMAH and KOH etching rate database, users can also customize the etching rate;

◆ Determine the effect of vertical etching in the case of coupled anisotropic etching;

◆ Three-dimensional graphics and cross-section visualization;

◆ Measure the distance and angle between any two points of the wafer after etching;

Comparison between experiment(top) and simulation (bottom)

Comparison between experiment(top) and simulation (bottom)

Wet etching is affected by temperature, etchant concentration and other parameters.

Related software

Product consultation

If you have any interest in our products, please feel free to leave us your intention information

相关应用

Learn how Intellisense can help you?

E-mail:china@intellisense.com

Add:No. 19, Lixin Road, Nanjing Jiangbei New Area, Nanjing City, Jiangsu Province

Copyright © 2022 Jiangsu Intellisense Technology Co.,Ltd. 苏ICP备08107867号 Powed by:300.cn SEO

Tel

Tel Messages

Messages Top

Top